Lorem Ipsum is simply dummy text

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Loading...

Strategic Partner of Contec Japan since 2000. We transform Indonesian factories into world-class smart manufacturing with proven IIoT solutions, Data Acquisition, Remote I/O, Long-range wireless communication/LoRa, Industrial Computers, Wireless LAN, and industrial automation expertise. Delivering complete edge-to-cloud integration where precision meets performance—empowering manufacturers to compete globally with confidence.

Contec Service Center Indonesia:

PT Tandem Technologies

Ruko Mall of Indonesia

Blok L1A, Kelapa Gading Square

Jln. Raya Boulevard Barat, Kelapa Gading

Jakarta 14240, Indonesia

Phone: (+62 21) 45869167, 45869157, 45869213

Products

Solutions

© Copyright 2017-2025, All Rights Reserved by Tandem Technologies Group

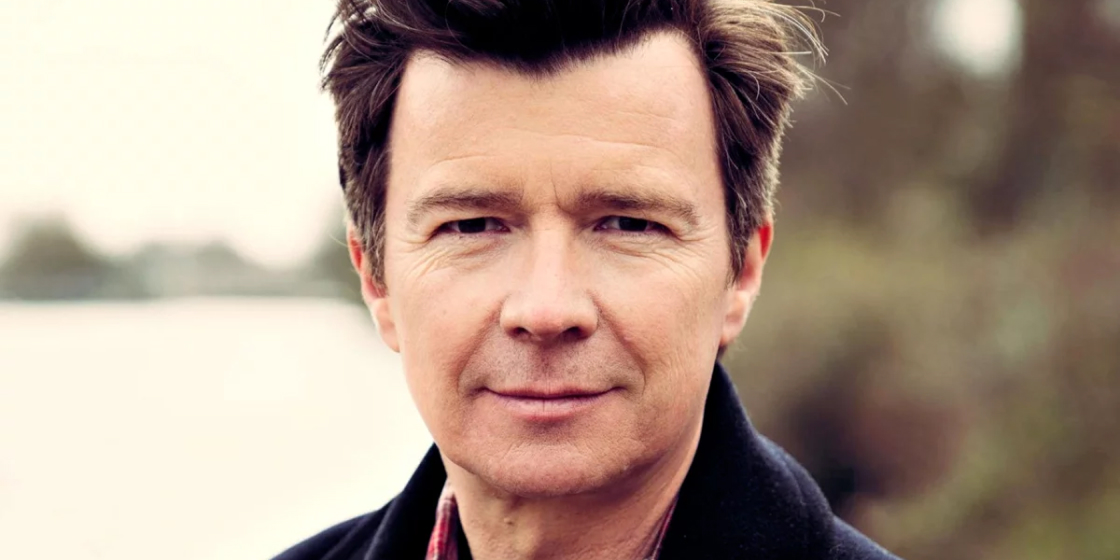

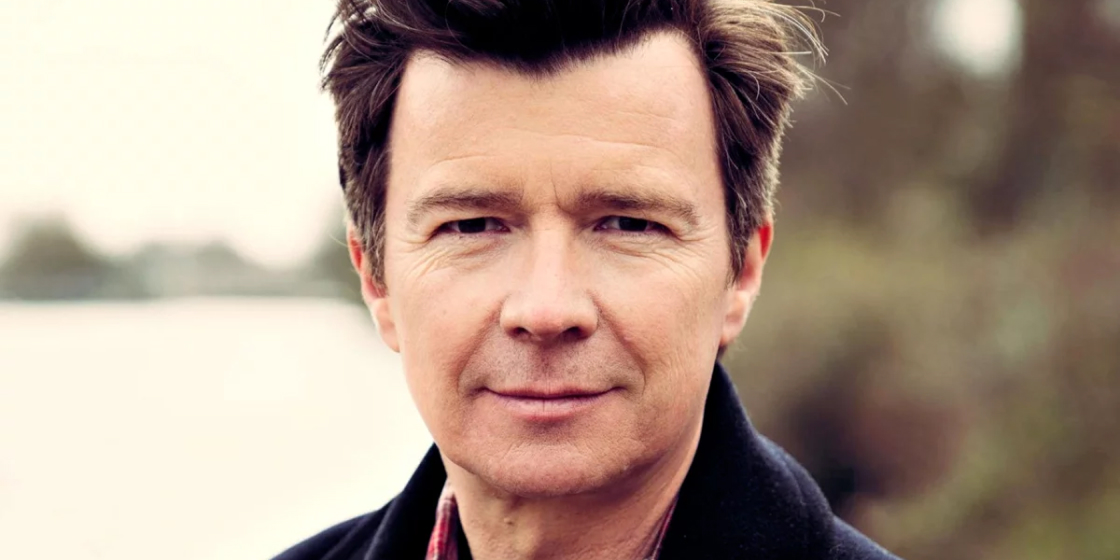

System Admin

Data Analytics Architect

Modern factories generate massive amounts of data, but data alone isn't valuable—insights are. Learn how to transform raw data into actionable intelligence that drives better decisions.

Manufacturing environments produce enormous data volumes:

A medium-sized factory with 100 machines, each with 20 sensors collecting data every second:

Focus on metrics that matter:

| Metric | Formula | Target |

|---|---|---|

| OEE | Availability × Performance × Quality | >85% |

| Throughput | Good Units / Time Period | Maximize |

| Cycle Time | Total Time / Units Produced | Minimize |

| First Pass Yield | Good Units / Total Units (first time) | >99% |

What happened? Historical reports and dashboards

Why did it happen? Root cause analysis and drill-downs

What will happen? Forecasts and trend analysis

What should we do? Optimization and recommendations

Process data as it arrives for immediate action:

// Real-time Quality Control

function analyzeProductQuality(measurement) {

// Analyze immediately

const isDefective = measurement.diameter < minSpec

|| measurement.diameter > maxSpec;

if (isDefective) {

triggerRejection();

alertOperator();

logDefect(measurement);

}

// Update live dashboard

updateDashboard({

currentQuality: calculateQualityScore(),

defectRate: calculateDefectRate(),

trend: analyzeTrend()

});

}

Process large datasets for deep insights:

Dashboard Design Principles:

- At-a-glance status: Use traffic light colors (green/yellow/red)

- Hierarchy: Most important metrics largest and top-left

- Context: Show targets, trends, and comparisons

- Actionable: Enable drill-down for details

- Real-time: Update automatically without refresh

Automatically identify unusual patterns that indicate problems.

Predict product quality based on process parameters before production completes.

Learn optimal machine settings for minimum energy consumption.

Predict future demand to optimize inventory and production schedules.

Data analytics transforms manufacturing from reactive to proactive, from guessing to knowing, and from lagging to leading the competition. Start with the basics, prove value, and scale systematically.

Data Analytics Architect

Expert in Industrial IoT and Smart Manufacturing solutions

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Discover how Industry 4.0 technologies are revolutionizing manufacturing. Learn about smart factories, predictive maintenance, and digital twins.

Let's discuss how our Industrial IoT solutions can help you achieve your digital transformation goals.

Contact Our Experts